It has been almost two years from the first time Mr. Barder and myself spoke about expanding his rod sales outside Europe. I had many choices to make at that time but really felt Edward was the right fit for West Slope. I am so glad that we both agreed it was a good time for both of us to venture out.

Mr. Barder is quite the gentleman in all respects. I really appreciate that about him and this has transferred over into the split cane rods that he builds. He designs his rods entirely in-house and his workmanship is uncompromising. Mr. Barder clearly shows he's a skilled craftsman of the highest caliber, if not one of the best I have seen!

So if you're Passion is for collecting or fishing one of the finest split Cane Rods made today then look no further. Barder rods fit the bill in all of these areas.

Mr. Barder is producing some of the most outstanding rods to come my way in years and now they can be made available here in the States. So I am very honored and pleased to be the exclusive dealer for the Barder Rod Co in the USA.

Please feel free to contact me if you have any question or special request. Thank You! Rick D. Sorensen

About Edward Barder

My father introduced me to fishing at a time when split cane rods were still commonplace, even though fiberglass was in the ascendant. We fished with rods made from both materials but it was split cane that I liked for its looks and its tactile qualities. I was one of those children who always had to dismantle things that interested them, and this habit led me to investigate the construction of split cane rods. Inevitably, attempts at making rods followed. The three stages of rod making - amateur, semi-professional and professional came in quick succession. Soon enough I found that working for Hardy's by day and making rods as a paying hobby at night was too much, so in 1990 I struck out on my own and started my career as a full time split cane rod maker.

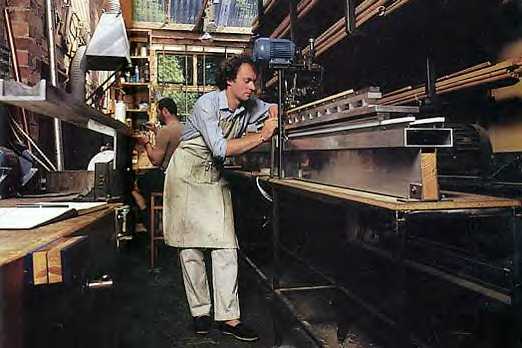

I now work with my old friend Colin Whitehouse. We make all parts of our rods in-house, except for the guides (we plan to make these too, as soon as we have time to equip ourselves to do so. We currently buy in guides which we hand-finish, straighten and finish bronze-black).

We are both very keen and frequent anglers and testing our rods is something we do very thoroughly and critically. Our sole aim is to make rods that are effective in a variety of contemporary fishing conditions, enhancing the angler's experience aesthetically without detracting from it technically.

Our rods are the result of a great deal of experience, fanatical attention to detail, and an unshakable desire to work to the highest standards possible regardless of cost or time. For us, it's fair to say that the artisan craft of rod making is a way of life that we are happy with. The huge resurgence of interest in split cane rods and the minutiae of their construction demonstrates that there are a lot more anglers out there with warm souls and good taste than one might have imagined when carbon fiber ruled the riverbank. Long may this state of affairs continue.

About Edward Barder Rods

Our precise, proprietary tapers incorporate fine tips that protect fine tippets and promote an action that is crisp, with excellent damping qualities and the ability to cast a tight, accurate loop. The middle third of our rods are designed so that they don't collapse when the rod is loaded during medium to long distance casts. The swelled butts of our rods are a particularly striking feature. They look even better in the flesh than in pictures. They have the most elegant and symmetrical shape possible. Such swells are not easily achieved, but they add greatly to the aesthetic qualities of our rods, and help to direct the angler's casting stroke with authority.

All fly rods come with a pair of perfectly mirrored tips, to be alternated in use from day to day. Supplied in a tailored poplin bag fitted with a stiffener to protect the tip sections, we also include a superb aluminium lined hand-made leather case of unsurpassed quality.

Culms are carefully selected from our large stock of seasoned Tonkin bamboo. They are flame tempered by hand, which drives out excess moisture and greatly increases the resilience and durability of the bamboo. Grain-split, the bamboo strips have their nodes hand pressed, straightened and staggered in the 3 X 3 configuration.

Tapers are precisely milled to tolerances of +/- one thousandth of an inch. The six segments are seamlessly bonded with heat resistant, waterproof adhesive. Our seasoned and properly straightened blanks have a distinctive rich honey tone.

Butt caps are discreetly engraved with our logo and finely knurled to match the sliding band and grip check.

Reel seats are made from our seasoned stock of highly figured Provencal olive wood, mortised to accept a reel foot perfectly and finished to a deep gloss.

Handles are turned from champagne-grade cork shives and are mounted with nickel silver grip checks and elegant winding checks.

Silk guide whippings are fully transparent and have the merest hint of olive tan and are tipped with super-fine tan silk. Non-cracking tan silk whippings secure the ferrule splints.

We make our ferrules from the best hard-drawn 18% nickel silver. They are hand-lapped to a perfect fit and are furnished with a stopper turned from the same wood as the reel seat.

Varnish used is the very best exterior quality and is both flexible and durable. Hand-applied, the resulting lustrous gloss finish is flawless.

Each rod has its model number and line rating inscribed on its underside in Indian ink, just ahead of the swelled butt. The tips are numbered too, just ahead of the ferrule whippings, and the tippings at the tip-tops are green for the No 1 & red for No 2.

Models and Prices

Two piece fly rods: $3,450 each

2783

6'6"

#3

2784

6'6"

#4

2843

7'

#3

2844

7'

#4

2903

7'6"

#3

2904

7'6"

#4

2905

7'6"

#5

2964

8'

#4

2965

8'

#5

21024

8'6"

#4

21025

8'6"

#5

21026

8'6"

#6

Three piece fly rods: $3,650 each

3904

7'6"

#4

3905

7'6"

#5

3964

8'

#4

3965

8'

#5

31024

8'6"

#4

31025

8'6"

#5

31026

8'6"

#6

Photos

Additional Info

The leather case is hand stitched natural vegetable tanned cow hide.

The hanging loop on the rod bag is also leather. The stiffener is American white ash.

The finish we achieve is, I sincerely hope, without equal. Ours may be the only silk wraps that are properly transparent.

The tipping (accents) to each wrap are the thickness of one strand of Pearsall Gossamer silk, but are actually six turns of single filament lace embroidery silk that was made specially for us. It's use requires a degree of skill!

We spend a lot of time hand dressing and straightening all guides as much as they'll allow. I then spend six hours plus stove enameling them all so that they are the same very dark bronze color. I use the same process that was employed to bronze guides and hooks in the old days. Please note the total re-profiling on the stripping guide feet. This is done with jewelers file and fine abrasives. It keeps the feet of the specially made carbide centered guide from being too fat and prone to silk thread/varnish breakdown.

The cork handle is made from corks that we cut to 3/8" ourselves, to get the best from each shive. We are quite proud of the wood-to-metal fit and finish of the reel seat and other handle components.

We triangulate and feather the ferrule splints to ensure a really smooth transition from bamboo to metal. Our ferrule station wraps are especially resistant to the usual cracking.

The split cane shafts are allowed to season for a long period (months) and we feel that the resulting rod is exceptionally straight and true due to the care taken to straighten it throughout its construction.

To maintain aesthetic and structural integrity, all nodes are kept as far away as possible from the butt swell, ferrule stations and tip-tops.

Our taper designs are worked out in-house. They are the result of years of testing, customer feed-back and formal analysis. This is not an exaggeration. Furthermore, we are able to make our split cane blanks to exact dimensions repeatedly. This is surprisingly unusual as far as we can tell.